Insulate, mate!

With the volt modding out of the way, it was then time for the teams to get their boards ready for sub-zero temperatures. The overclockers would be cooling CPU and GPU (and in some cases north bridge as well) down to below -100˚C, which means that there will be a build up of condensation over time.It’s important to stop this from becoming an issue – this is done by insulating the vital areas of the motherboard that are going to get rather cold over the course of the afternoon.

There were a variety of very different methods employed by the teams, but the basic premise was the same – to make the areas around the CPU socket, north bridge, PCI-Express and memory slots waterproof.

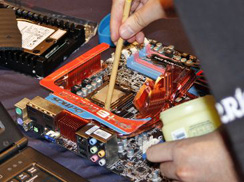

The first of the methods we’ve shown below (top three pictures) was probably the simplest – it literally involved painting the board with Vaseline, ensuring that all of the capacitors were sealed. A piece of neoprene was then cut to fit around the CPU socket and covered the surrounding area – notice that holes for the capacitors and components surrounding the CPU socket were not cut out.

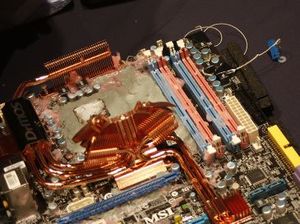

Team Australia drew templates of the area surrounding the CPU socket and northbridge on a piece of paper and then transferred the positioning onto a piece of neoprene – this was then cut to fit around all of the capacitors. Once these pieces had been cut, the team then focused on sealing off all of the slots, sockets and connectors on the board so that it could be sprayed with waterproofing spray – it was one of the neater insulation jobs at the event.

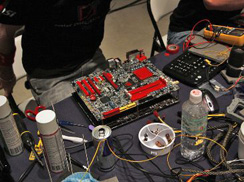

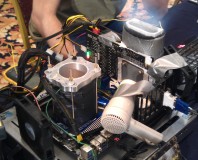

Team Turkey used a combination of modelling clay and grease to insulate their motherboard – it was probably the messiest of the insulation jobs, but it was nevertheless an effective solution to the problem. The CPU was secured in place and the modelling clay was moulded around the socket to prevent any condensation making it into or underneath the socket.

Grease was then applied around all of the heatsinks, which Turkey interestingly left in place unlike many of the other teams. The PCI-Express and memory slots were smeared with grease as well in order to prevent condensation getting inside the slots – they also laid modelling clay around the edges of these slots as well in order to stop unwanted liquid from getting under the slots and potentially stopping the boards from working.

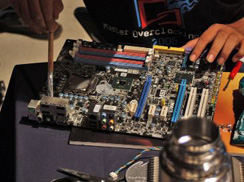

Indonesia’s methodology was very simple – it involved simply spreading Vaseline around the CPU socket, capacitors, PWMs, northbridge, memory and PCI-Express slots and then covering the board in a neoprene cut out. Finally, South Africa employed something that was quite different to anyone else – they essentially covered the board and graphics card in insulation tape, which seemed to work really well even though it looked a little strange.

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.